SMEs are the drivers of the national economy as it contributes a large part of GDP. It is found in India that these units are spread across states in a scattered way. Thus when any program is initiated on the development of these units like training and development, it is very hard to get all entrepreneurs in a commonplace. To solve these issues Ministry of Micro, Small, and Medium Enterprises are focusing on Cluster Development Programs (CDPs) for MSMEs.

Clusters are defined as the accumulation of units in a specific geographical area which produces similar products using similar production technologies. This concept evolves from the Co-operative movement concept where a common structure is used to gain economies of scale, benefits of economic policies, and lenders can also find it easier to provide finance. The clusters are moved on to achieve a common goal.

The clusters comprise similar kinds of units so this also fosters healthy competition among the units. and also encourages business growth for them. Currently, there are more than 400 modern SME clusters and more than 2000 rural artisan clusters are operating in India.

In West Bengal, presently 183 clusters are operating successfully under the Directorate of MSME.

MSME Cluster Development Program (CDP)

This program aims to foster growth among the units which are under a single umbrella. The group of enterprises that comprises similar business activities and technologies, share a common identifiable and contiguous geographical area, forms a cluster. Like in South 24 Parganas in West Bengal, there are 8 clusters among which 3 clusters are there which produces Jeans Pants which we use regularly. They supply their products to local markets like Gardenrich, Metiaburuj in Kolkata which markets their products. The training programs can be organized on a single node so that everyone in a single cluster can join the program. The CDPs mainly look at the following areas –

- To support the SMEs to improve their skills, technology, performance, productivity, market outreach, product and service quality, better access to capital, etc.

- To help to foster development by creating Self Help Groups (SHGs), associations, and consortiums so that they can increase their bargaining power.

- To upgrade the current infrastructures and facilities by creating Industrial Parks and Flatted Factory Complexes.

- To create Common Facility Centers (CFCs) as a testing hub not only for raw materials but also for finished products and services testing and also a facility for making complementary production processes.

How Likely the Scheme Will Work

This scheme is supposed to help in creating and developing clusters in the following manner–

- Diagnostic Studios which help to make a SWOT analysis of the business units. This also facilitates the clusters to meet and solve their problems by themselves.

- Soft Intervention Techniques by organizing Seminars, Workshops, Training Programs, Counselling Sessions on different areas like Finance, Marketing, etc. to help the clusters to cope up with challenges.

- Detailed Project Report (DPR) to be created to check for the financial and technical viability of the projects to be evaluated by experts of different fields. The DPR will be scrutinized thoroughly by Banks or other consulting firms.

- CFCs to be set up at different clusters to speed up the programs.

- Creation of Infrastructure Development Centers (IDCs).

The financial aids depend on the level of activities performed at different levels –

- For Diagnostic Studios, the maximum project cost will be ₹2.5 lakhs

- For Soft Intervention the maximum cost should be ₹25 lakh of which 75% of the incurred cost will be Govt. aid. This would scale up to 90%, for clusters that comprise more than 50% of women-led units, micro, and village units as well as SC or ST units.

- For CFCs maximum project cost should be not more than ₹15 crores, of which 75% of the incurred cost will be Govt. aid which will scale up to 90% for the clusters that comprise more than 50% of women-led units, micro, and village units as well as SC or ST units.

- For IDCs the maximum investment should not exceed ₹10 crores of which 60% will be Govt. aid and for backward states or clusters with 50% women or micro, village, SC, or ST clusters it will be 80% of the incurred cost.

Practical Evidence:

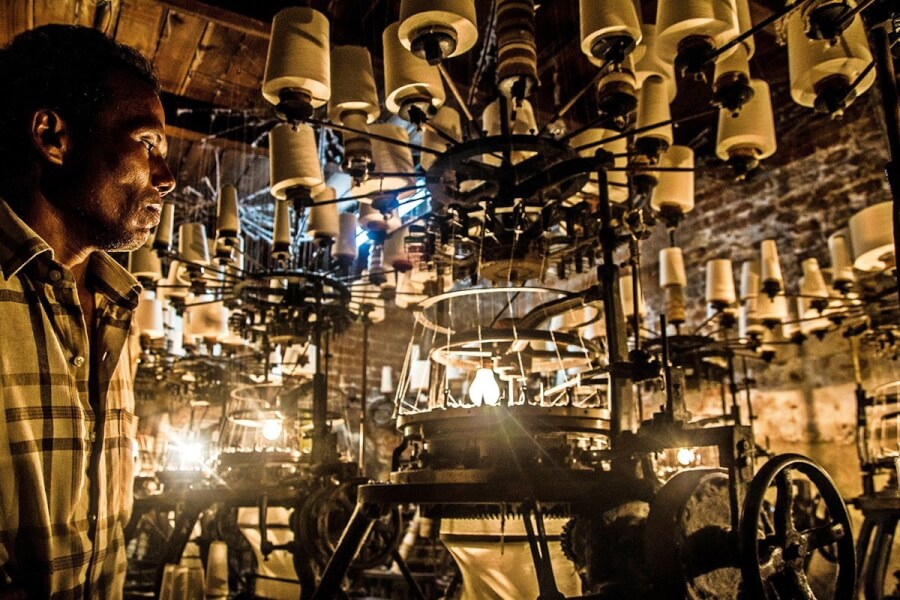

Recently on a visit to one of the Garment Manufacturing Cluster in South 24 Parganas, near to Sundarban, which consists of 25 people manufacturing the Jeans Pants. The raw materials like the fabric, cotton needed for stitching, buttons, chains, everything provided by the “Mahajans” or big businessmen from Metiaburuj, Gardenrich, Khidderpore, etc.

Initially, they use to do the job individually, there was no such co-operation among themselves. They use to get the work by physically meeting the Mahajans and the rate per piece of finished product varies from one to one based on their skills and bargaining power. The “Master” who has long experience used to get high rate than the young ones who have started the job recently.

The CDPs have changed their approach completely. When the program was initiated, there was confusion among the people because they take all their counterparts as their competitors. But how can this be converted to strength, that was not known to them? Also, the titbits of business operations, daily cash management, marketing skills, all are new to them. The soft intervention projects with (in some of which I also took part) aim to develop these skills in them, helps a lot to face the ever-changing market. Initially, they use to return the finished product to the Mahajans, who use to just put a sticker of a brand and sell at a high margin. Now they are stitching the brand name of their own and sending it to market. The competition among themselves helps them to grow business faster with the help of CDPs. This may be a short example but numerous clusters are functioning excellently in West Bengal as well as in India under the same concept.

Challenges

CDPs mainly aims to develop rural SMEs. This program faces the following challenges –

- From competitors to partners, it is a very tuff journey in rural India with very basic or nill knowledge about how to run business.

- Little faith in outside agencies who are consultants of CDPs

- Land issues to establish CFCs or IDCs.

- Poor infrastructure in rural areas.

- It’s very hard to raise interest in this kind of program for first-generation entrepreneurs.

- Traditional to the modern approach of business modeling – the journey is quite troublesome.

Conclusion

In a recent study, it was shown that almost 70% of the manufactured exports of India are from the SME Clusters. Some of the SME clusters are so big that they account for almost 90% of the production output of that particular product, e.g. the knitwear cluster of Ludhiana, the Gems and Jewelry Export cluster in Surat and Mumbai, the leather cluster in Chennai, Agra, and Kolkata, the Rubber Cluster in Tripura, Bamboo cluster in Assam and North East India.

Some clusters are so specialized that no other country can match their expertise like Paithani sarees in Maharastra, Tant in West Bengal. These clusters stand out in terms of specialties and traditions.

In this ever-changing market, SMEs suffer to stand out of their own. Only cooperation through this kind of program can help them to outperform their competitors.

*Co-authored by Mr. Mainak Chakraborty , Teaching Assistant, School of Management, Adamas University

Comments are closed.